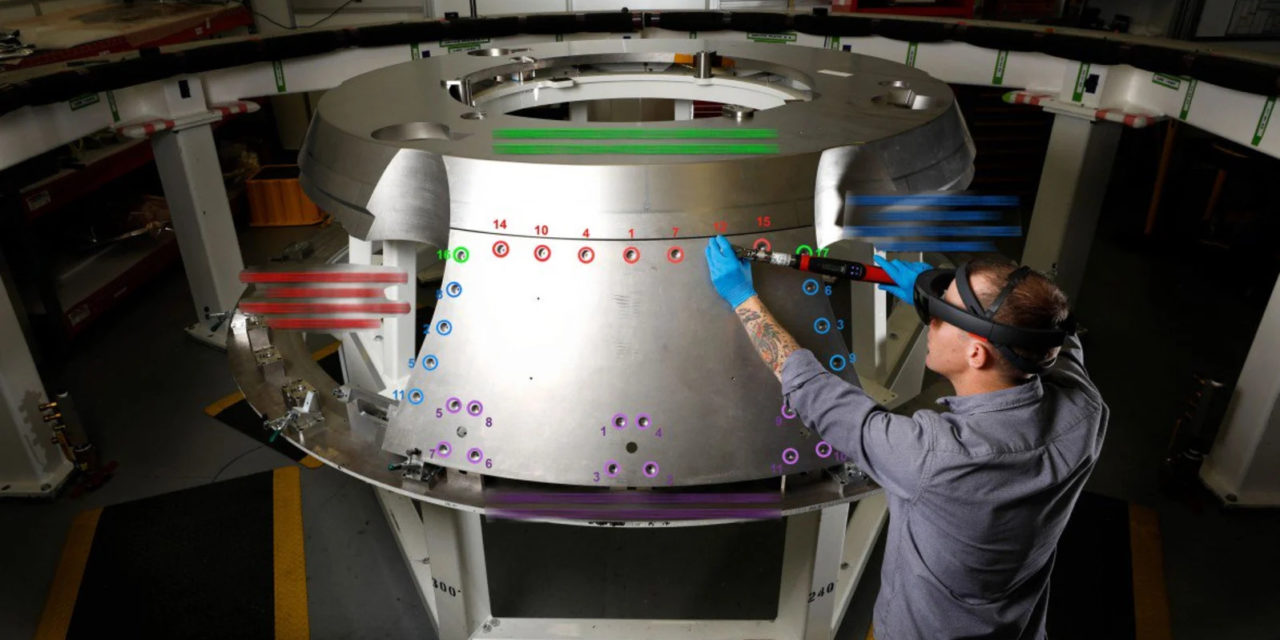

To construct NASA’s Orion Spacecraft, Lockheed Martin integrated Scope AR‘s augmented reality (AR) tools in its space division to expedite building times and save costs. According to a report by EE Times, Scope AR developed AR how-to manuals and live chatting features with remote experts that support the assembly of spacecraft components. For workers, the time to interpret assembly instructions was reduced by 95%, along with an 85% reduction in overall training time and a more than 40% boost in productivity.

“When the quality department is looking to verify component placement in assembly, AR is a very quick and easy way to do that,” said Shelley Peterson, Principal Investigator for Augmented and Mixed Reality for Lockheed Martin Space Systems, in an interview with Engineering.com. “When they verify the work instruction in advance, it’s much quicker to do that through AR than to try to verify from traditional methods.”

By using AR to empower their workforce, Lockheed Martin was able to realize cost savings across their company. As an example, Peterson noted their use of fasteners. The company’s space division realized savings of roughly $38 per fastener. Though this figure initially sounds insignificant, the aerospace manufacturer purchases over 2 million fasteners per year, thus leading to $76 million in savings – and that’s just for one type of part.

“You need to make sure [AR] brings instant expertise and context to the task at-hand,” said Scott Montgomerie, founder, CEO and CTO of Scope AR, in a blog post on his company’s site. “You don’t want to add another layer of process; you want to ensure workers can access knowledge from subject matter experts or resources, wherever they are and whenever they need them.”

Leveraging AR platforms to streamline workflows has already seen great strides and investments from other industry stakeholders. Popular manufacturing AR headset developer RealWear recently acquired the technology behind Kopin’s Golden-i Infinity Screens, on top of $80 million that they received in funding.